Product Item: J23 Open Punching Machine

Murata Punching Machine Specifications of mechanical power press:

1.High precision ,wide application

2. ISO certification

3.High performance

4.Easy to operation

The machine of whole structure and characteristics :

1. J23 Series High Precision Presses mechanical power press is one of the new generation of plate process and developed by Maanshan Press And Shear Machinery manufacturing Co.,Ltd ,The punching machine is for cutting, punching, blanking, bending and light stretching work.

2.C Type Steel welded frame, high rigidity and less deformation Compact,wide body frame eliminating vibration for improved ide life and machine.

3. Rigid construction guarantees exact die mating,Six side long rectangle guides of the slide with high moving precision and high accuracy, extending the service life of the die.

4. Highly advanced, rigidly supported gears, operate in oil bath without any noise saves space, reduces, shaft deflection, increases gear life.

5. High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

Features of mechanical power press:

1.J23 series mechanical power press are general open tilting power press with simple structure,reliable performance and easy operation .J23 punching machine can adopt rigid turn-key clutch .

2.So, it is convenient for operation and maintenance .J23 mechanical power press can also adopt

emergency stop service to make the slider block suddenly stop on the range of 0- 135 degree,and the photoelectrical protector device is optional .

3.J23- 100 and J23- 125 mechanical power press are special among the J23 series .

Their main body is cast in iron .The cranked axle is settled vertically .Eccentric sleeve makes easy adjustment .And there is also pneumatic friction.Therefore ,J23- 100 and J23- 125 mechanical power press enable to work with small impact and sationarity and make slider block stop at any position

3. Safety Standards:

●Safety standard(2006/42/EC)

●Opening electric cabinet door cuts off power

●China-made pedal switch (safety grad: 4)

●Left and right safety fence confirm to CE standard

●Safety relay monitor pedal switch, safety protection

4. Hand Punching Machine Technical Date:

| No |

Technical Parameter |

Unit | JB23-80 |

| 1 |

Nominal Pressure |

KN |

800 |

| 2 |

Nominal Pressure Stroke |

mm | 5 |

| 3 | Slider Stroke | mm | 115 |

| 4 |

Slider Stroke Times |

mm | 45 |

| 5 | Max.Closed Height | mm | 410 |

| 6 | Die Height Adjustment | mm | 60 |

| 7 | Distance from Slider Center to Machine Body | mm | 280 |

| 8 |

Bolster Size(F﹒B*L﹒R) |

mm | 500*750 |

| 9 |

Bolster Blanking Hole Dia. |

mm |

200 |

| 10 |

Slider Subface Size( F﹒B*L﹒R) |

mm | 250*300 |

| 11 |

Shank Hole Size(Dia*Depth) |

mm | 60*100 |

| 12 |

Columns Interval |

mm | 360 |

| 13 |

Bolster Thickness |

mm | 90 |

| 14 |

Max. Inclined Angle of Machine |

° | 20 |

| 15 |

Motor Power |

Kw | 7.5 |

| 16 |

Motor Speed |

R/Min | 1440 |

| 17 |

Machine Outline Size( L*W*H) |

mm |

1600*1300*2600 |

| 18 |

Weight |

T | 4.5 |

|

Please contact us for other parameters. |

|||

5. Accessory List:

Standard

Optional

No

Accessory

Model / Manufacturer

Configuration

1

Main Motor

China-made High Performance Motor

2

Electrics

Schneider- France

3

Safety Fence

Left and Right Safety Fence

4

Lubrication System

Manual Lubricating Cap

5

Pedal Switch

High Quality Pedal Switch-China

6

Photoelectric protection

LNTECH- Shandong

7

Main Motor

Siemens-Germany

8

Lubrication System

Auto lubrication-China

9

Safety standards

CE CSA NR-12 OSHA

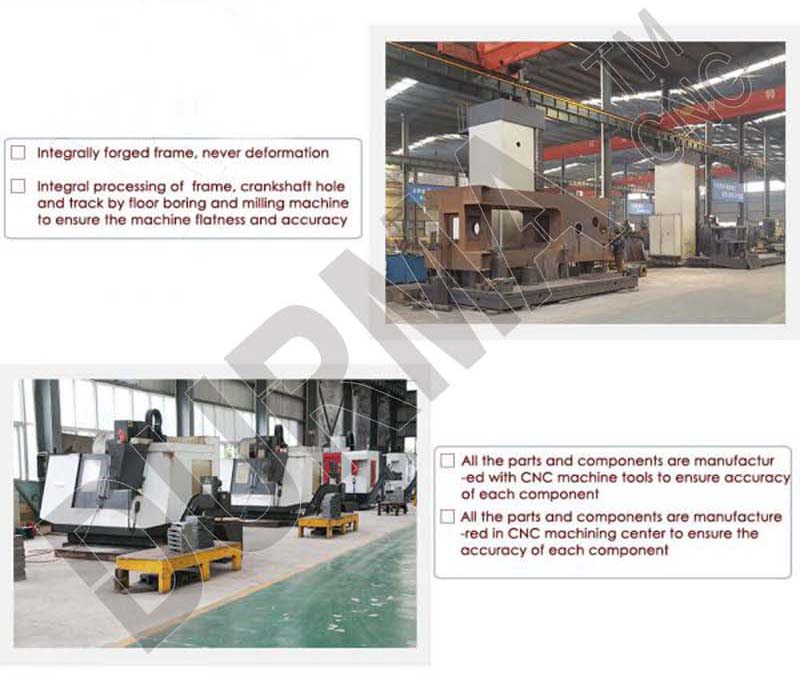

Office Punching Machine Fabrication Equipment:

Maanshan Press And Shear Machinery Co., Ltd. was founded in 1988,Our product line encompasses hydraulic metal punching machine,hydraulic embossing press machine,four column hydraulic press and more. If you don’t see what you need listed here, please do not hesitate to contact us for more information.

English

English français

français español

español