-

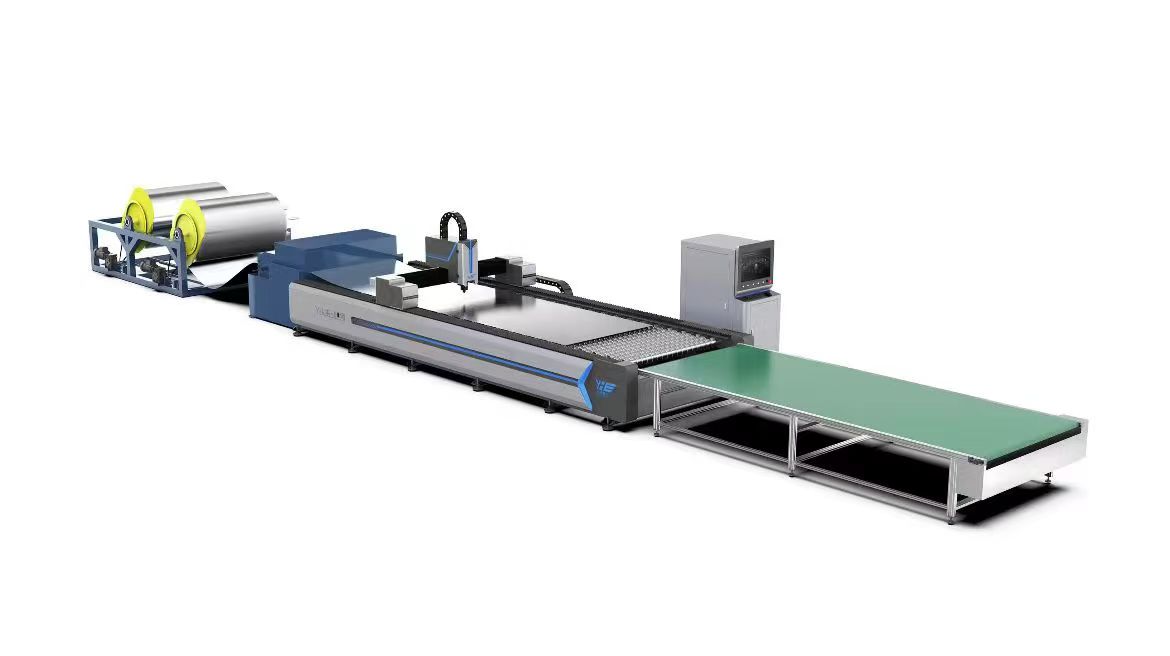

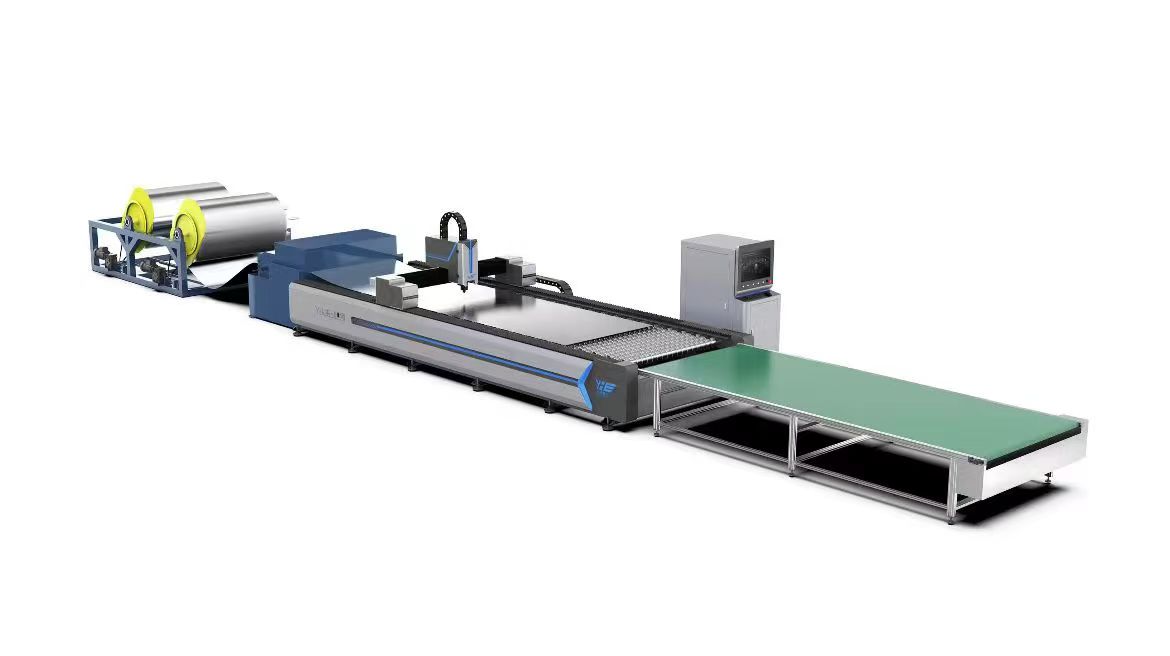

Stainless steel galvanized plate ventilation duct cutting and blanking machine Coil Blanking - Laser Cutting - Table feeding

read more

-

How to ensure that the acceleration of the laser cutting machine reaches 1G? New machine configuration: high-speed small single unit, RAYTOOLS X3S + BM110E Motovario reducer, innovance drive, 1.5K W-Y1, Y2, X-1 W, Z axis with 400 watts brake, all electrical appliances Delixi, proportional valve SMC, solenoid valve airtac, rack German Retsen, Guide rail Taiwan SMS, plate welding 6...

read more

-

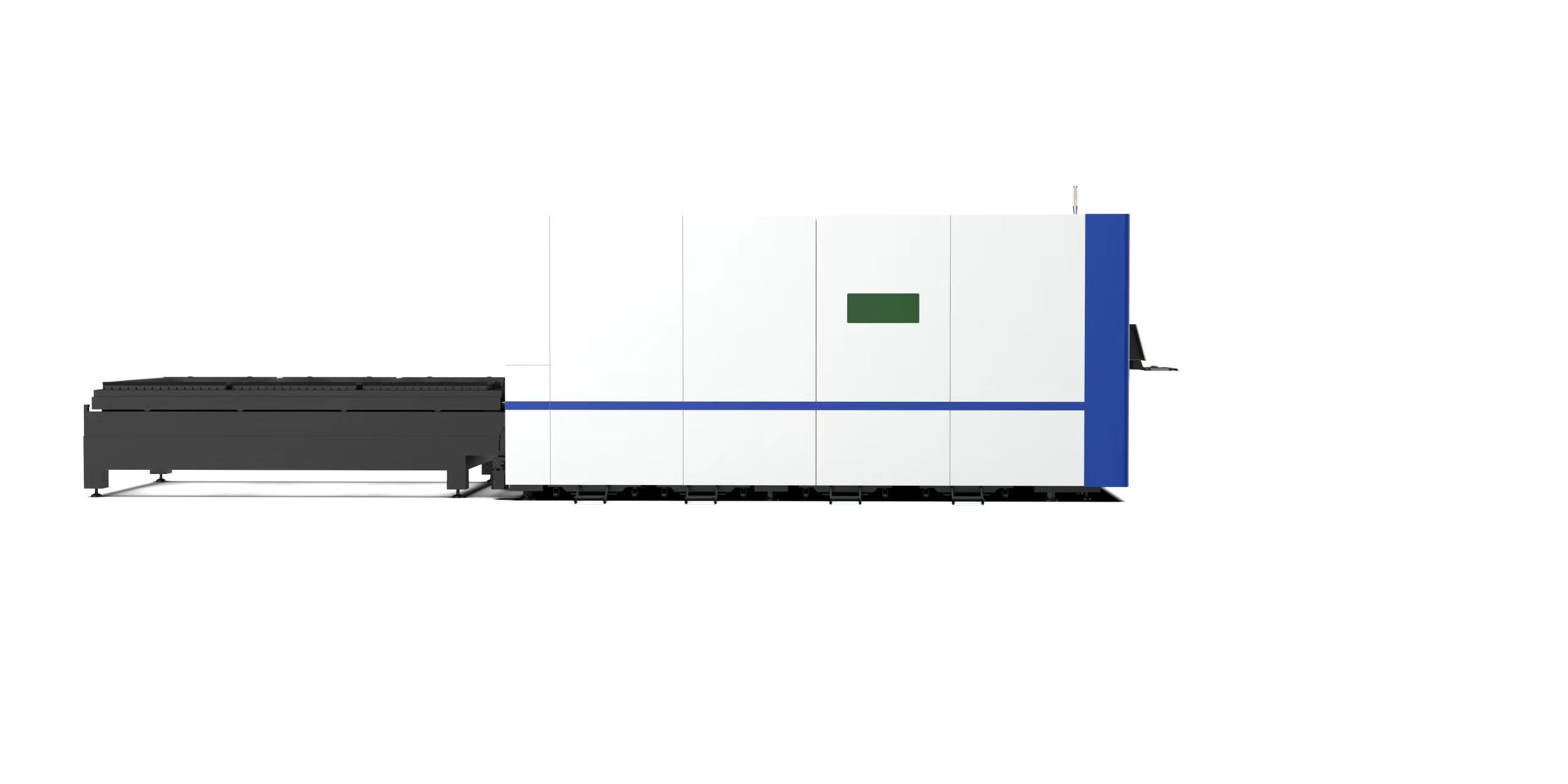

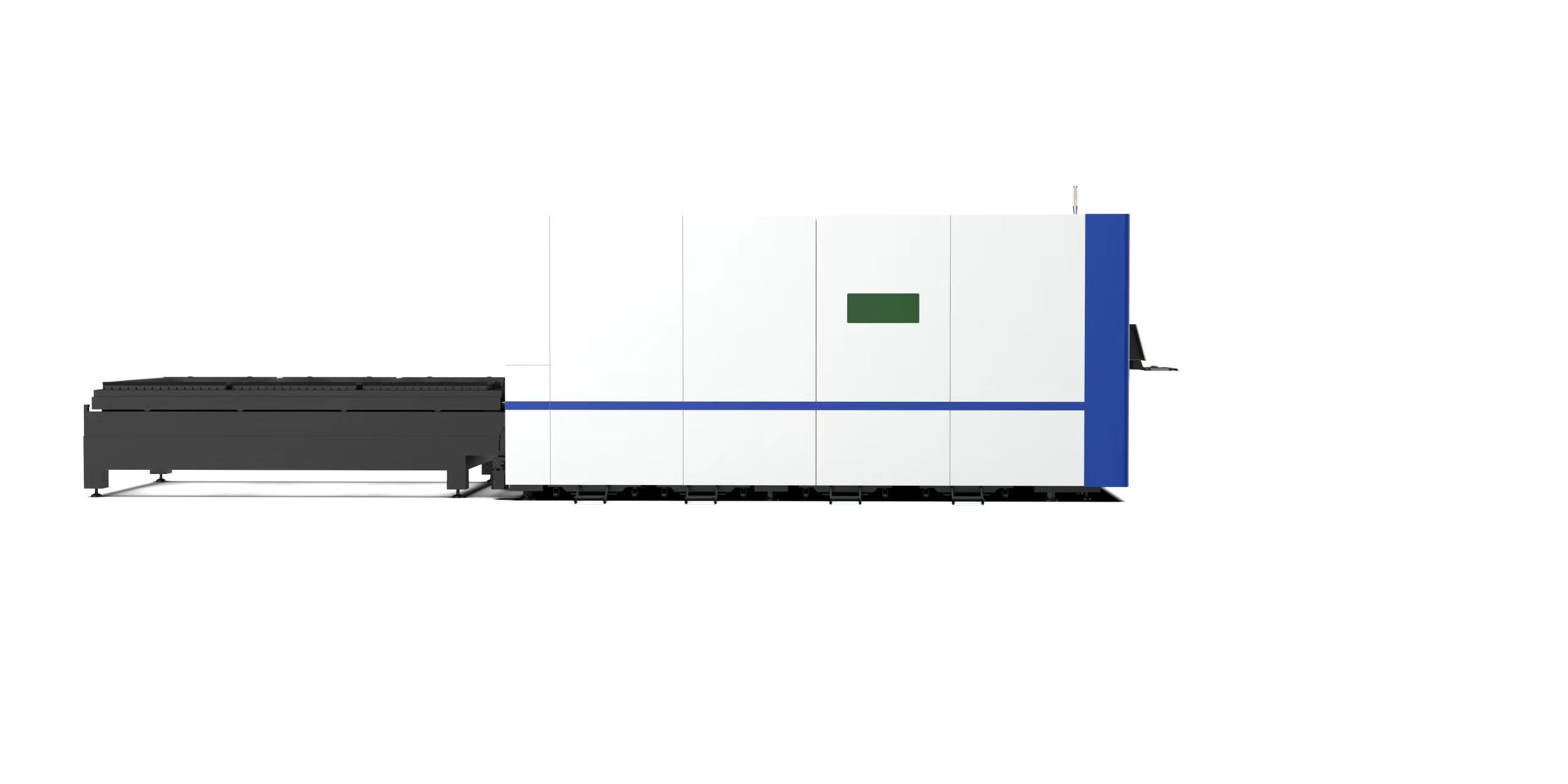

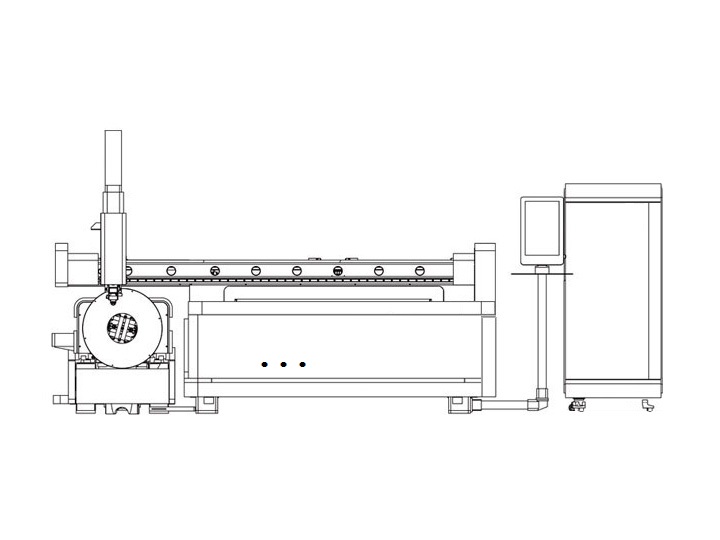

Generally we use the fiber laser cutting machine at size 3000x1500mm 4000x2000mm 6000x2000mm 6000x2500mm 8000x2500mm But sometimes customer need the exchange table for save the time for loading and unloading the metal sheet

read more

-

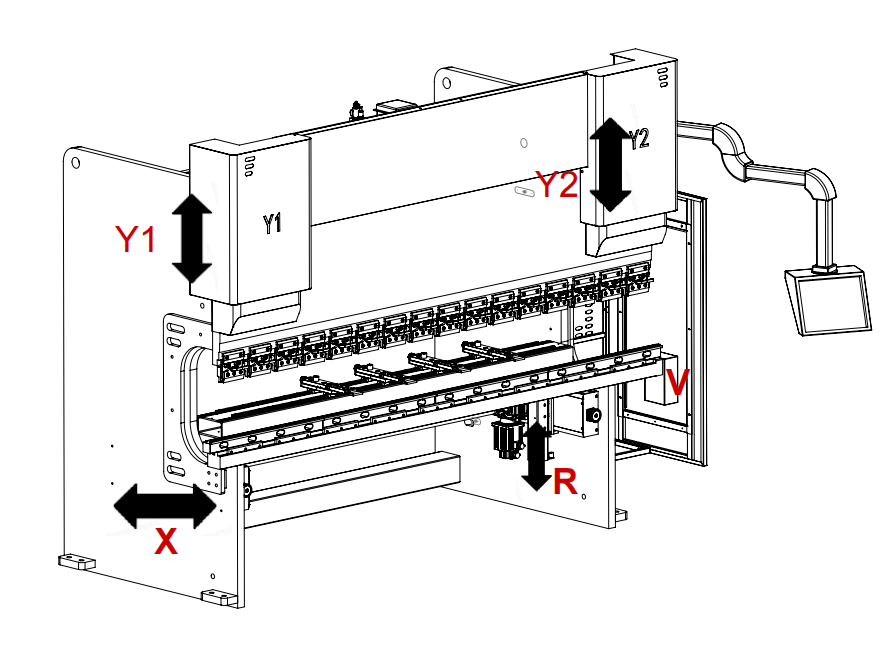

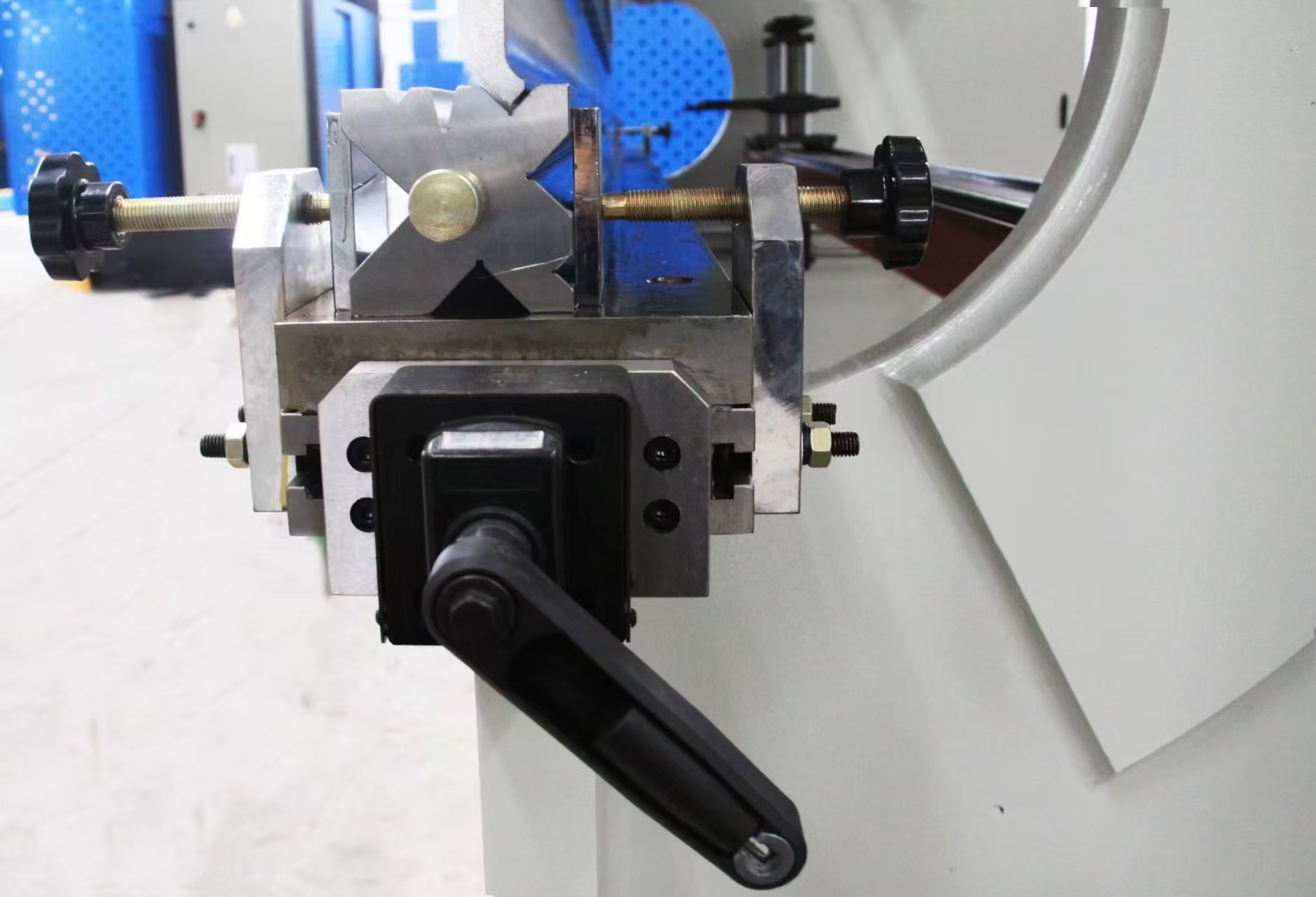

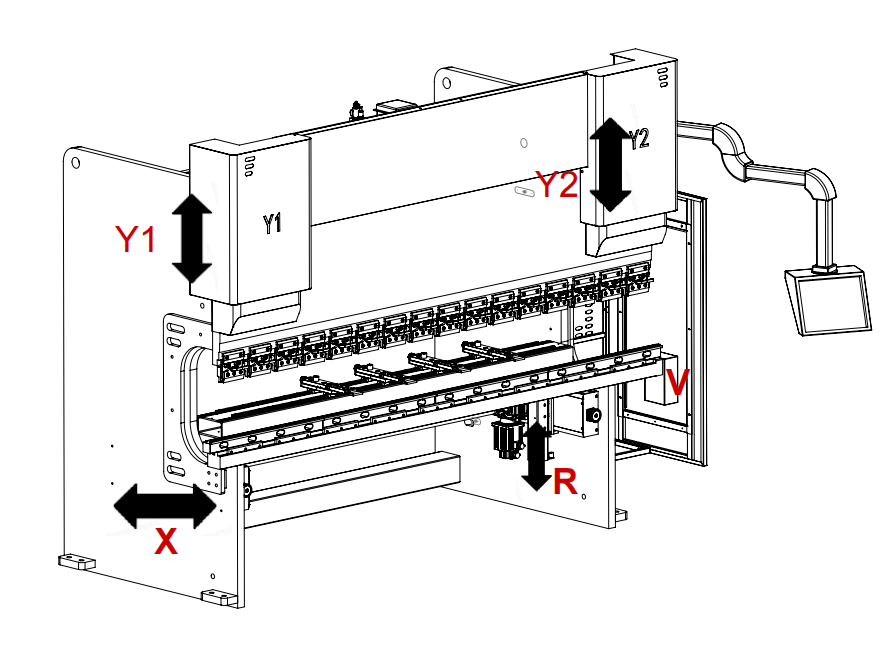

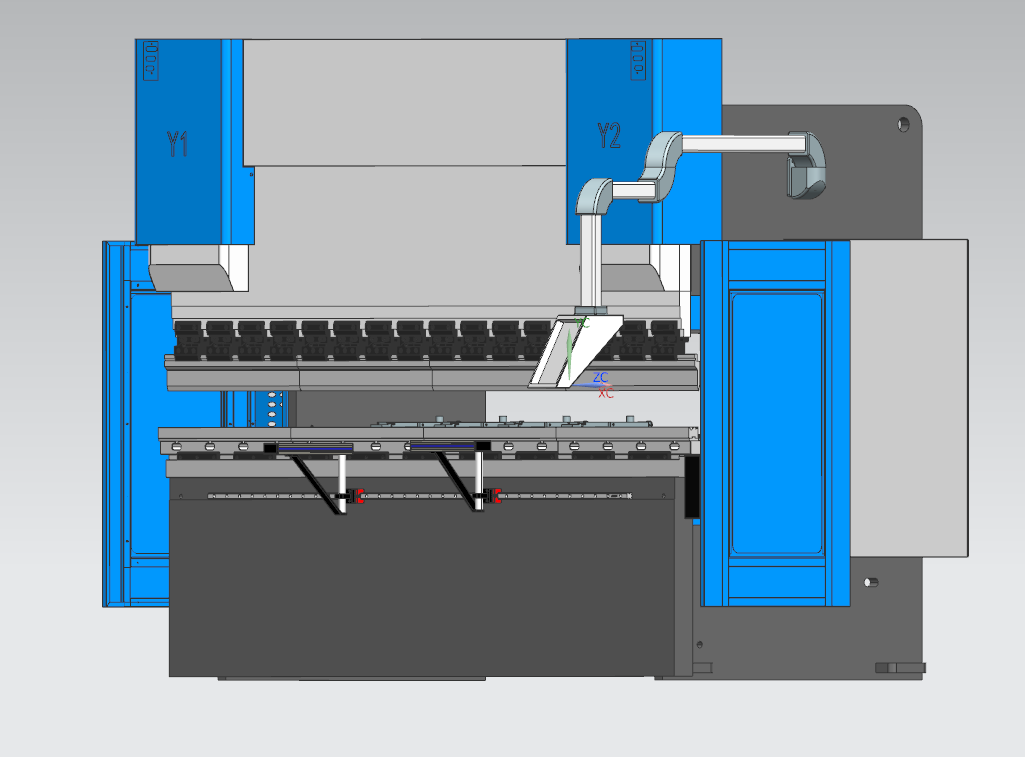

Now there are many pressbrake of cnc control in China The most popular is 4+1 which means Y1 Y2 X R +V Y1 Y2 are for the stroker for the pressbrake bending force direction and X for stop the material and R for rise the backgauge And the V is mechnical defelction for the bended metal sheet Another is 6+1 Y1 Y2 X R Z1 Z2 +V Y1 Y2 are for th...

read more

-

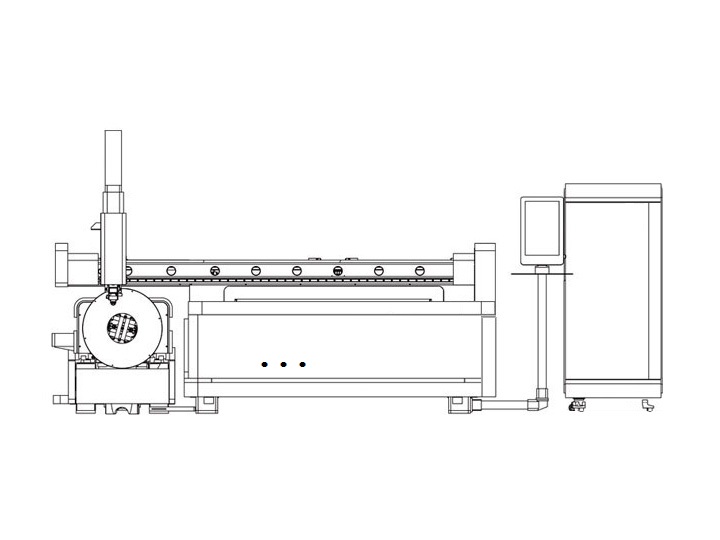

How to choose the fiber laser cutting machine made in China Now in China have two famous fiber source : Maxphotonics & Raycus And for the laser cutting head we have raytools and Boci from Cpycut For the CNC controler System we have Empower and Cpycut Now we always BM110 & BLT 310 When you buy a fiber laser cutting machine you also need the air compressor and voltage regulator Cutting...

read more

-

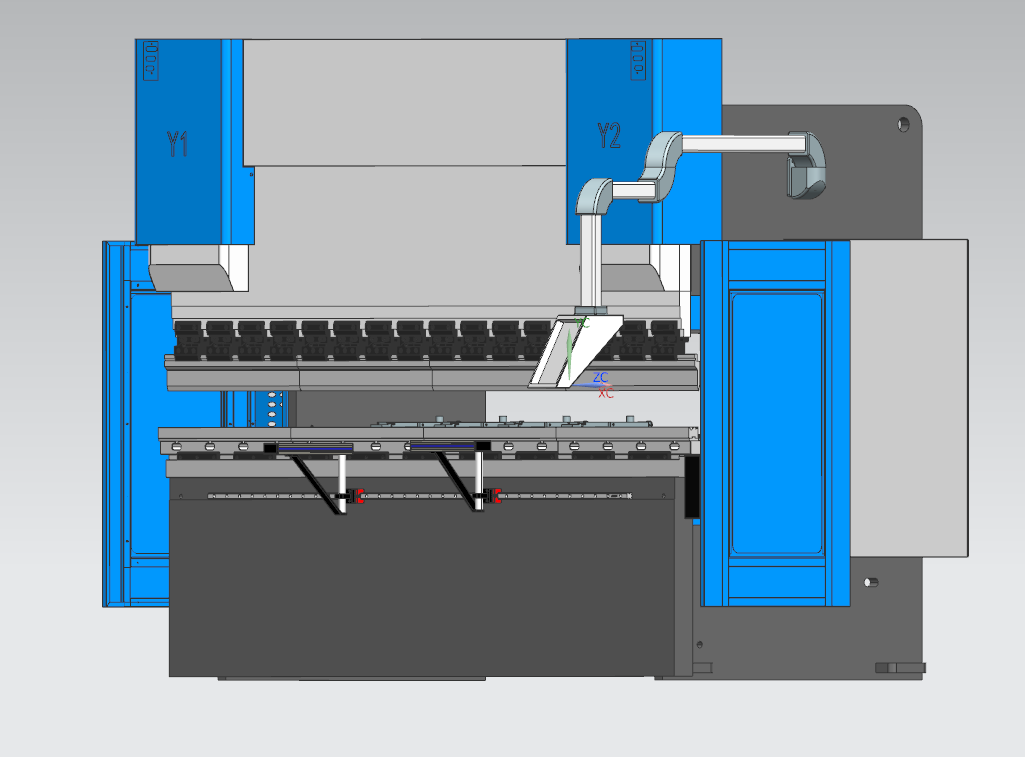

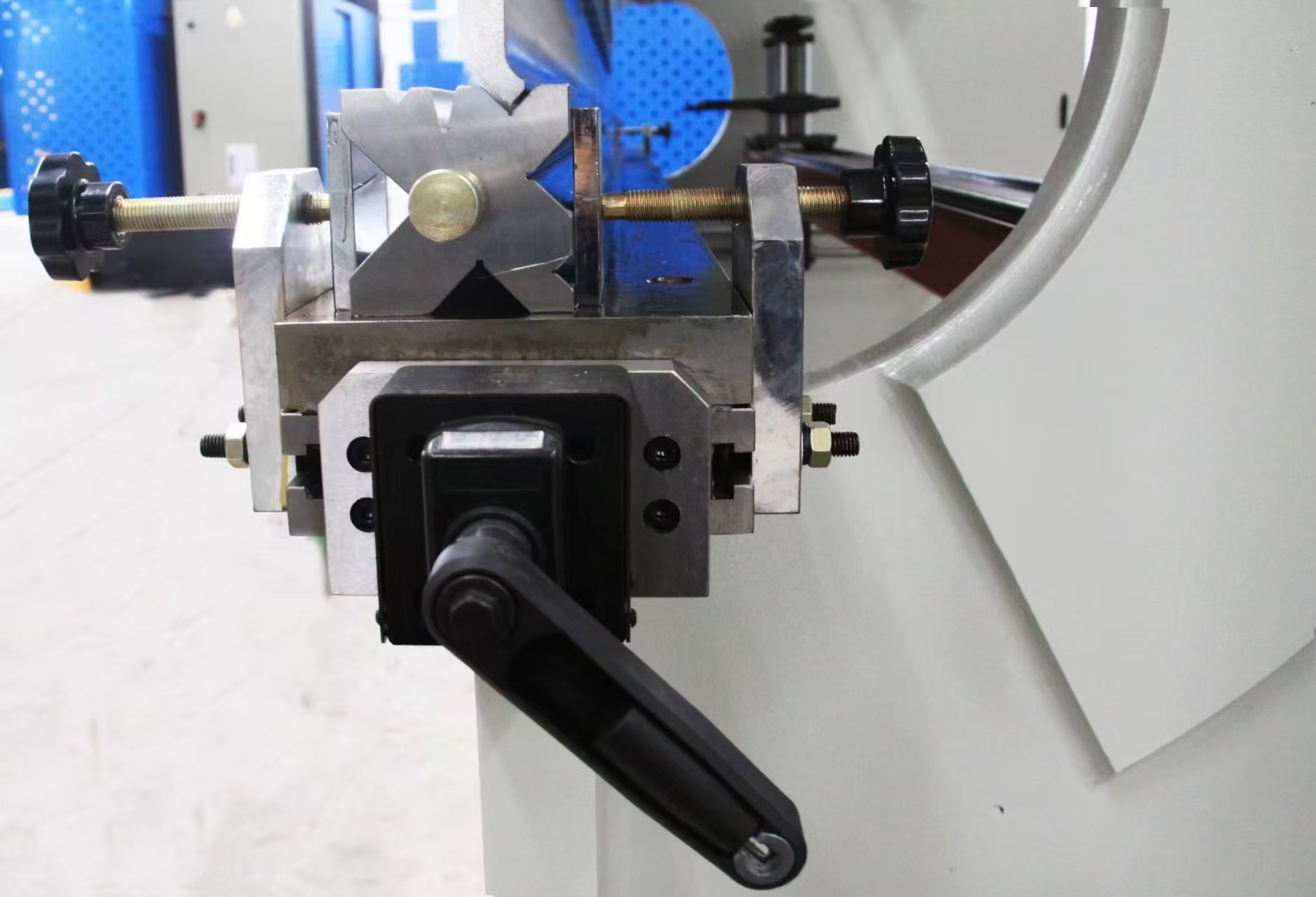

press brake is a machine with twins oli cylinders for bending the stroker to the metal plate After bending force you take five poitn for meassure the Angle of the bend metal for example A1 A2 A3 A4 A5 It will happened A1= 90 DEGREE A2= 91 DEGREE A3= 93 DEGREE A4= 91 DEGREE A5= 90 DEGREE So as this moment we need a cowning system to balance the angle for one full lenght of metal sheet for Nc ...

read more

-

Hydraulic Shear Maching is for cold cutting for steel plate Mainly hydrualic cylinder trassmission for make the blade cut the metal And have the NC controler control the X axis from 0-600mmm And also have the front support arms three for support the metal plate when it is heavy and huge Generally now people use fiber laser cutting but still some people donnt know how to use the fiber laser c...

read more

-

Press brake have 4 plates Right wall plate Left wall plate Storker plate And workbench plate 100T3200mm press brake we always have L R= 50MM Stroker 60mm workbench 80mm

read more

-

Material Cost Material cost refers to the net material cost required by the drawings, calculated as material volume * material density * material unit price. The primary cost here is the material cost, and with this, a simple quotation can be made using a “materials plus labor” approach. For example, if the material cost is one dollar, using a “materials plus labor” quotation would be two dollars....

read more