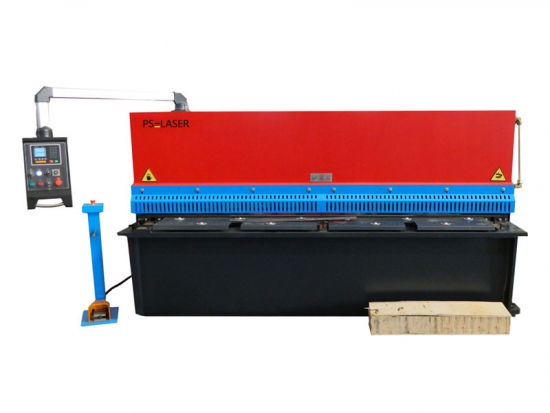

Product Item:Hydraulic Swing Beam Shearing Machine

Hydraulic Shearing Machine Main Features:

1. Streamlined design originated from EU, machine frame using overall welding and annealing treatment.

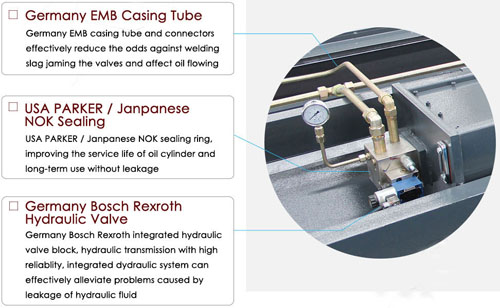

2. Reliable Germany Rexroth integrated hydraulic system and hydraulic transmission, which can effectively reduce problems caused by leakage of hydraulic fluid.

3. Hydraulic swing beam shearing machine is a kind of equipment swinging the upper blade to shear plate with smaller shearing angle and distortion, improving shearing quality.

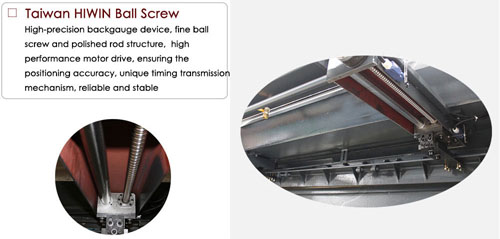

4. Backgauge is adjusted by high‐precision ball screw driven by E21S controller, during the process frequency convertor prevent positioning device horizontal swinging, significantly improving positioning accuracy.

5. Light aligning device, convenient for manual operation; pressure cylinder with built‐in spring mechanism and bottom end furnished with special material gasket to prevent aluminum or other softer materials from being imprinted.

6. Made by high‐quality alloy tool steel, the machine can meet the requirements of impacting load and high wear resistance when working.

7. Light and practical cantilever referring to man‐machine engineering design, easy NC operation interface with features of high precision and more comfortable.

8. The worktable adopts the rolling steel ball to reduce the frictional resistance, protect the work piece surface; novel protective devices complying with safety specifications: protecting the operator’s personal safety; exquisite design: petty material can be cutter easily.

9. Front material supporter is equipped with Perpendicularity and positioning regulator to ensure the cutting accuracy, easy operation,practical and efficient.

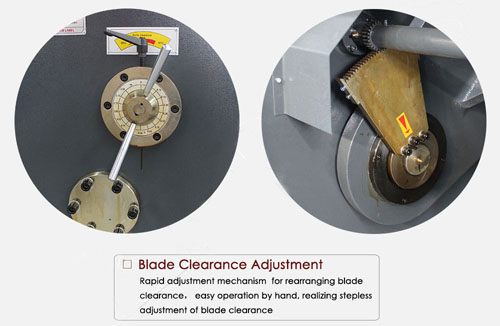

10. Rapid adjustment mechanism for rearranging blade clearance, simple operation by hand and stepless adjustment.

Standard Configuration:

● ESTUN E21S CNC controller

● DELTA frequency converter

● HIWIN ball screw and polished bar, control accuracy 0.05mm

● Germany Bosch Rexroth integrated hydraulic valve

● Germany Schneider electrics

● Light align

● South Korea KACON petal switch

● Backgauge X‐axis electric control

● Controller suspension arm and front material supporter

● Germany EMB oil tube connector

● Germany Siemens main motor

● Hydraulic and electrical overload protection

● Blade materials ( 6CrW2Si )

Safety Identification:

● Safety standards ( 2006 / 42 / EC )

● Open the electrical cabinet and front safeguard door to power off

● Domestic pedal switch (safety grade 4)

● Rear metal safeguard rail, CE standard

● Safety relay monitors pedal switch, safety protection

ESTUN E21S CNC system:

● High‐definition LCD panel

● Control motors and frequency converters

● X‐axis intelligent positioning

● Multi‐step programming, 40 programs, each program 25 steps

● Built‐in time relay

● One‐button switching function

● Unilateral positioning function

● One‐key backup and restore parameters

● Both Chinese and English language

● Metric/British system

Specification Parameters:

| Shearing Capability(mm) | Back Gauge (mm) | Shearing Angle(°) | Throat Depth (mm) | Motor Power (KW) | Net Weight (kg) |

Dimension

(LxWxH)(mm)

|

| 4×2000 | 20-600 | 1.30 | 150 | 4 | 3200 | 2750x1500x1600 |

| 4×2500 | 20-600 | 1.30 | 150 | 4 | 4000 | 3300x1500x1700 |

| 6×2500 | 20-600 | 1.30 | 150 | 7.5 | 5800 | 3200x1650x2000 |

| 6×3200 | 20-600 | 1.30 | 150 | 7.5 | 7000 | 3900x1650x2000 |

| 6×4000 | 20-600 | 1.30 | 150 | 7.5 | 9000 | 4750x1800x2200 |

| 8×2500 | 20-600 | 1.30 | 150 | 11 | 6000 | 3200x1700x2280 |

| 8×3200 | 20-600 | 1.30 | 150 | 11 | 8300 | 3900x1750x2280 |

| 8×4000 | 20-600 | 1.30 | 150 | 11 | 9500 | 4750x1800x2200 |

| 10×3200 | 20-600 | 1.30 | 150 | 15 | 9500 | 3900x1850x2200 |

| 10×4000 | 20-600 | 1.30 | 150 | 15 | 11000 | 4800x1900x2280 |

| 12×3200 | 20-900 | 1.30 | 150 | 18.5 | 12000 | 3900x2200x2200 |

| 12×4000 | 20-900 | 1.30 | 150 | 18.5 | 15800 | 4850x2280x2450 |

Please contact us for other parameters |

||||||

Standard/Optional Configuration List:

| No | Accessory | Model / Manufacturer | Other | Configuration |

| 1 |

CNC System |

E21s NC System ESTUN |

Standard |

|

| 2 |

Electrics |

Schneider Electric ‐ France |

Travel switch & Limit switch |

|

| 3 |

Main Motor |

Siemens Motor ‐ Germany |

||

| 4 |

Backgauge, Timing Belt, Timing Pulley |

Taiwan |

Positioning control Guaranteed Precision |

|

| 5 |

Frequency Converter |

DELTA‐Taiwan |

||

| 6 |

Pedal Switch |

KACON ‐ South Korea |

||

| 7 |

Hydraulic System |

Bosch Rexroth ‐ Germany |

||

| 8 |

Oil Pump |

Sunny ‐ USA |

||

| 9 |

Sealing Ring |

PARKER – America / NOK‐Japan |

||

| 10 |

Oil Tube Connector |

EMB ‐ Germany |

||

| 11 |

Front Safety Guard |

PS | ||

| 12 |

Back Safety Guard |

PS | ||

| 13 |

Back Blanking Plate |

PS | ||

| 14 |

Backgauge |

HIWIN Ball Screw and polished rod ‐Taiwan |

||

| 15 |

Back Pneumatic Holder |

PS |

Optional |

|

| 16 |

Before‐cutting Feeding Device |

PS |

||

| 17 |

Front Photoelectric Protection |

LNTECH ‐ Shandong |

||

| 18 |

Back Photoelectric Protection |

LNTECH ‐ Shandong |

||

| 19 |

Safety Standards |

CE CSA NR‐12 OSHA |

|

|

English

English français

français español

español