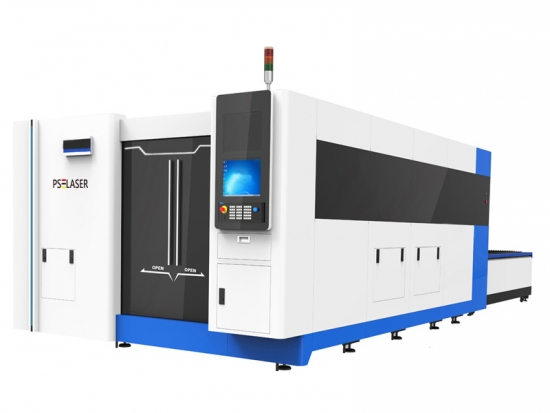

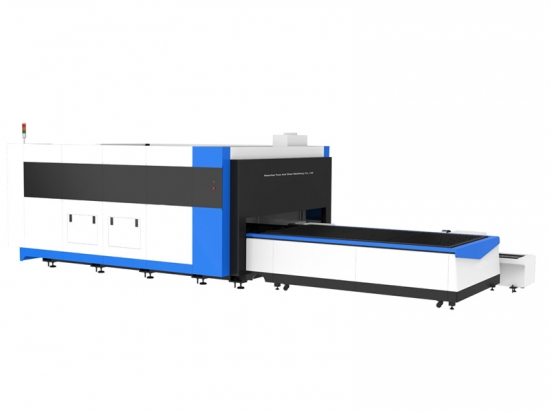

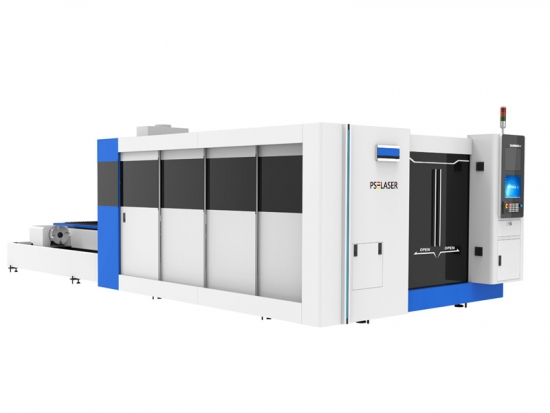

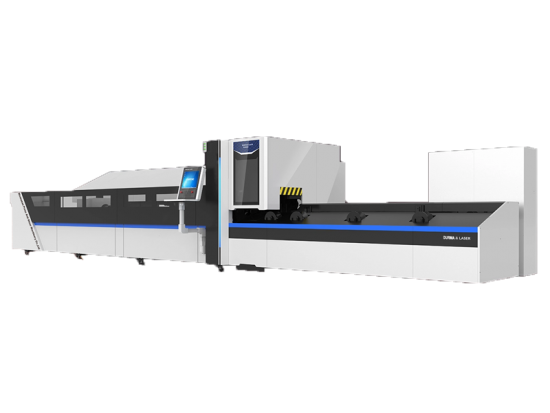

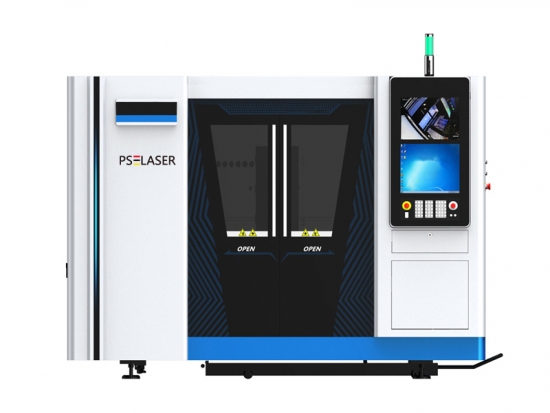

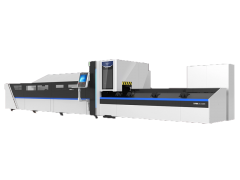

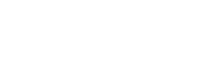

Product Item: Full Cover Plate And Pipe Fiber Laser Cutting Machine

Configuration List:

Fiber Laser Source

Raycus/IPG

Fiber Laser Cutting Head

Raytools/WSX

Servo Drive System

Schneider/ Delta

Liner Guider System

Lapping/THK

Transmit System

Dual Rack & Pinion type

Pneumatic Component

SMC/AirTac

ElectricSystem

Schneider

Motor Reducer

Motovario

Nesting Software

Cypcut

Exhaust Blower

Included

Water Chiller Unit

S&A

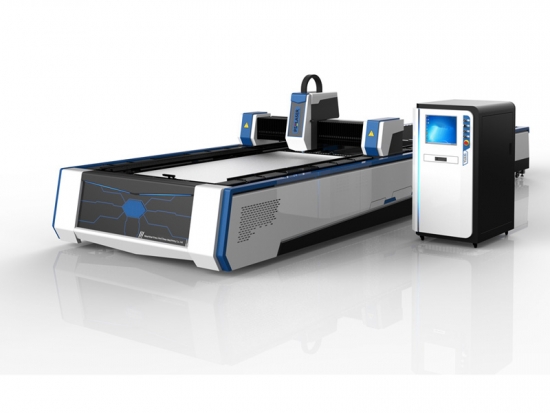

Steel plate welding

Gantry welding machine tool with high temperature heat treatment and aging treatment to ensure a smooth and high-speed cutting equipment reliability

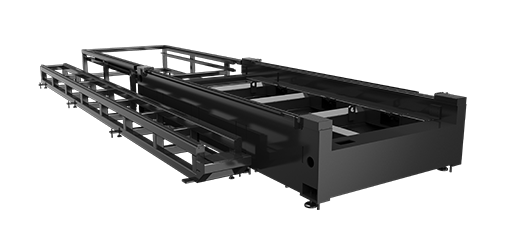

Cast Aluminum Beam:

Cast aluminum beam experienced artificial aging treatment before the finishing machining, which makes its hardness level be T6, together with abrasion resistance and oxidation resistance. The beam is very light because of aluminum material, which makes the speed of manufacturing higher.

Fiber Laser Source

1. Fiber Laser Module

2. Low Energy Consumption: Save energy and protect environment

3. Photoelectric conversion rate is up to 25-30%

4. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine

5. Lifetime is more than 100,000 hours

6. Almost free maintenance.

Water Cooling system

Water cooling system, the temperature of the refrigeration unit in digital chart shows, while water temperature more than a specified temperature, it will automatically refrigeration; while water temperature below a specified temperature it will automatically stop.

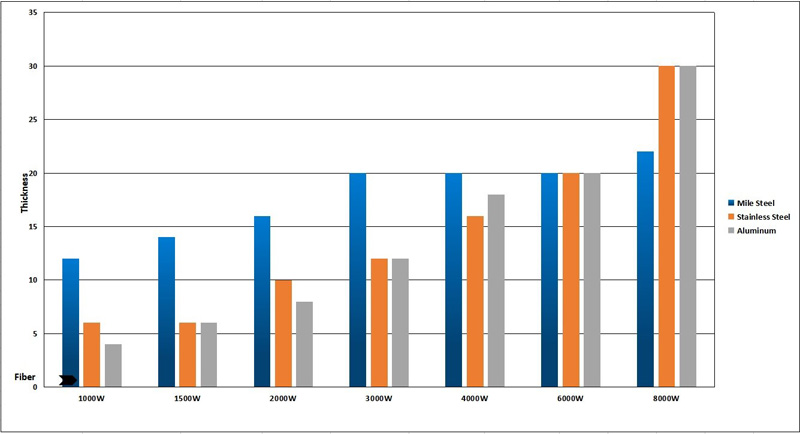

Cutting Parameter:

Fully Enclosed Laser Cutting Machine Product Parameters:

| Model | PS3015 | PS4020 | PS6020 | PS6025 |

| Working Area (L*W) | 3000*1500 mm | 4000*2000 mm | 6000*2000 mm | 6000*2500 mm |

| Laser Output Power | 8000w/6000w/4000w/3000w/2000w/1500w/1000w | |||

| X/Y-axis positioning accuracy | ± 0.05 mm | |||

| X/Y-axis repositioning accuracy | ± 0.02 mm | |||

| X/Y-axis Max. linkage speed | 130 m/min | |||

CNC Laser Tube Cutting Machine Cutting Samples:

English

English français

français español

español