VMC Vertical Machining Center

① 24Arm ATC

② air gun and water gun

③ Chip conveyor

④ 11KW spindle

⑤ Spindle BT40-8000rpm

⑥ Electrical cabinet CE

⑦ Call light、Work lamp

⑧ Full enclosed splash guard

⑨ water box

⑩ water pump 2 pieces

⑾ Auto lubrication systerm

⑿ Air blast

⒀ USBinterface+MPG

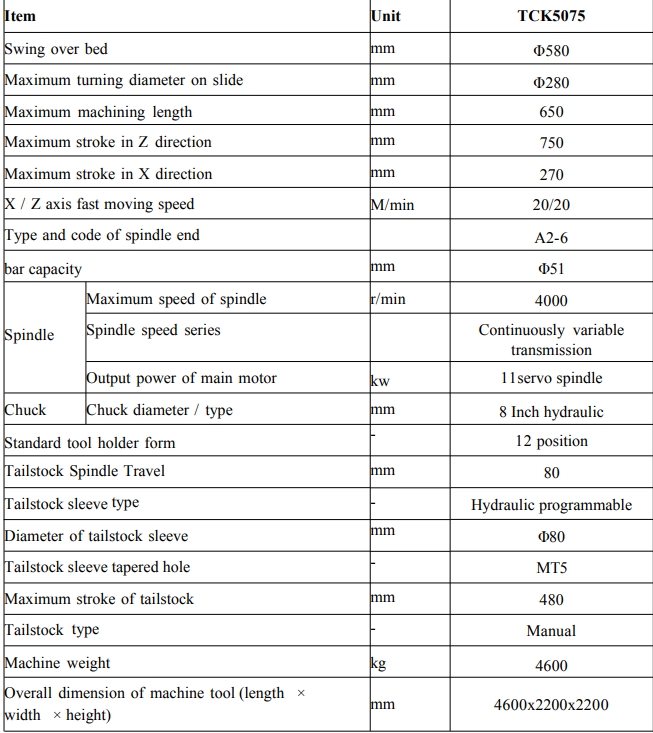

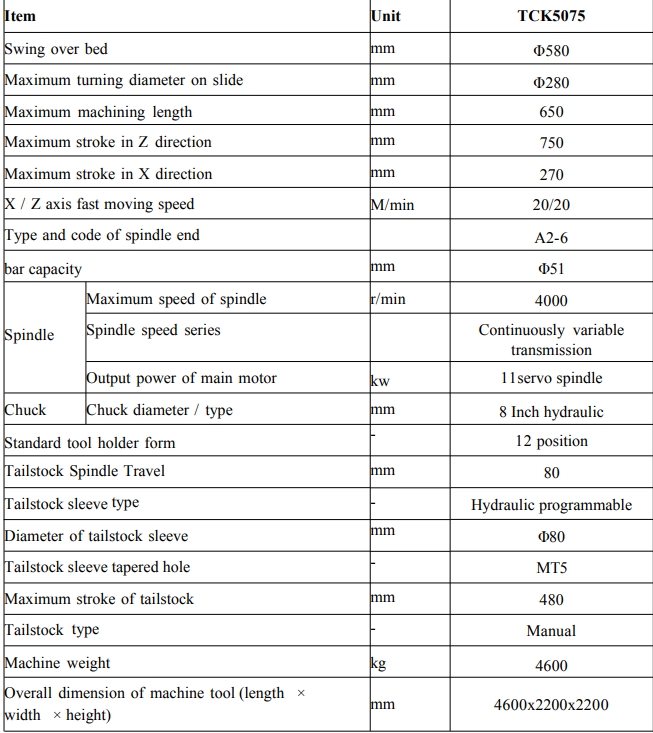

Processing scope X-axis travel (left and right) mm 1100 Y-axis travel (front and rear) mm 600 Z-axis travel (up and down) mm 600 Distance from nose end of main shaft to working surface mm 120-720 Distance from spindle center to column rail surface mm 650 Table specifications Table size (x-axis direction) mm 1200 Table size (Y-axis direction) mm 600 T-groove of worktable mm 18X5X100 Maximum load of worktable kg 800 Spindle specification Spindle speed rpm 8000 Recommended horsepower of spindle kW 11-15 Taper of main shaft inner hole BT40 feed system G00 rapid feed (X/Y/Z axis) m/min 32/32/24 G01 cutting feed mm/min 1-8000 Servo motor specifications Nm 22 X22 X 22 Tool magazine system (OPT) Magazine capacity ATC Arm 24 Weight approximately KG 6000 Length * width * height Wooden box 3600*2300*2550

Num configure Specification details Manufactor Origin 1 Control system Oi MF PLUS Fanuc Japan 2 X/Z/Y axis servo motor 20Nm Fanuc Japan 3 Special bearing for three axis screw Inner diameter 30, outer diameter 62 NSK Japan 4 Three axis ball screw 4012 HIWIN Taiwan 5 X/Y /Zaxis rail Taiwan original p-roller PGH45/45/45 roller HIWIN Taiwan 6 spindle BT40-150-8000rpm OKADA Taiwan 7 Knife cylinder 4.5T AirTAC Taiwan 8 Tool magazine BT40-24 OKADA Taiwan 9 electrical Schneider Germany 10 Positive displacement automatic lubrication system TZ-2202-210XA river valley joint venture 11 Three axis locking nut YSF M30*1.5P Ying tin Taiwan 12 Triaxial coupling C65L90 Three wood Japan Random attachments: Num Name Specification or mark Num 1 Handle of spring chuck MAS BT40-ER32 1 2 Clip spring 6、8、10、12、16、20 1 3 Pull nail P40T-1-MAS403 1 4 Adjustable sizing block and bolt Self made parts 8