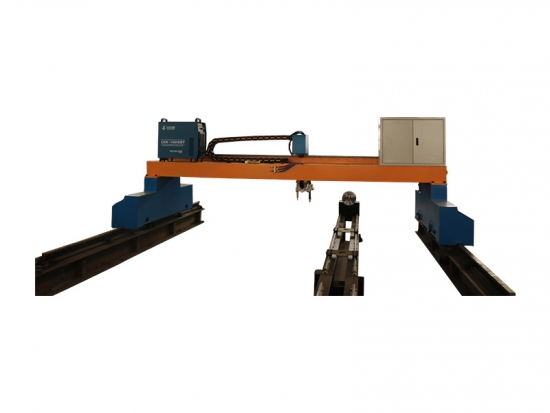

Product Item:CNC Plasma Cutting Machine

Hypertherm CNC Plasma Cutting Machine Main features:

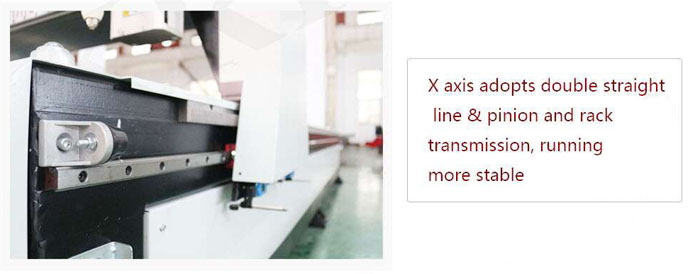

1. The CNC plasma cutting machine is desktop gantry structure with double-side drive. X & Y axes track are precise cylindrical linear guide rails, precise gear and rack drive, runs stably.

2. Machine frame adopts the whole welding and annealing treatment, main frame is made by medium-sized steel pipe through welding; rail base plates are made through the planer precision processing, high strength, good precision and no deformation.

3. Crossbeam, side panels and all movable parts are made by aluminum alloy through fine casing and milling, with features of high strength and small inertia, ensuring the high strength and avoiding the cutting positioning instability caused by high inertia.

4. Adopting HP105 portable arc-pressure height regulator which can automatically regulates the height between cutter and plate to ensure the cutting quality. Scientific structure can effectively avoid collision between cutting head and steel plates owning to reaction rate cannot matches with that of cutting head.

5. Specimen closed environmental bottom groove and dust treatment system timely discharge dust and provides a healthy working environment for workers.

Standard Configuration:

● Shanghai Fangling F2300A CNC system

● X-axis Y-axis using linear track, Z-axis using ball screw

● HIWIN ball screw and polished rod, control accuracy 0.05mm

● Movable operation system

● FASTCAM/SMARTCUT CNC cutting software

● Japanese Panasonic P80 cutting head

● X-axis with double motor drive, Y-axis single motor drive

● France Schneider electrics

● Safety standard(2006/42/EC)

Shanghai Fangling F2300A CNC system:

● Up to 45 commonly used graphics libraries

● Graphics scaling, rotation, mirroring functions

● Graphics matrix, interleaved, and repetitive

● Automatically limit the speed in the corner according to the thickness of the steel plate, effectively prevent over-burning

● Quickly convert between metric and imperial measurements

● Graphical steel plate calibration

● Coordinate system is customizable

● Customizable IO

● Backup system and parameters, online upgrade

● All Chinese / foreign language (English, Japanese, Russian, French, other custom language) operation menus, easy one-key switch between Chinese and foreign languages.

● Line or number is selective

● Support edge cutting, offset cutting

● With power-off and breakpoint memory-protecting function

● Dynamic / static processing graphics display, graphics zoom in / zoom out, dynamic tracking cutting point under the amplified state

● Compatible with Wentai, TYPEIII |, PM2000 and other special nesting software

● File storage: electronic storage disk, 1G

● User program space: 1G

● Control accuracy: ± 0.001mm

Arc-pressure height regulator:

● HP105 portable arc voltage height regulator is designed for portable CNC cutting machine and light gantry CNC cutting machine.

● Embeddable cabinet panel, good integration, simple wiring

● New design, using SMT (Surface Mount Technology) and latest chip

● Comprehensively enhance the stability and anti-interference ability of the machine, adding a variety of protection circuit

● With liquid crystal display, real-time display status and parameters, simple and intuitive

● Built-in "isolated voltage plate", can match 1: 1 or 50: 1 arc voltage input

● Intelligent arc voltage, control accuracy, manual speed, automatic sensitivity and other parameters are adjustable

● Fully functioned, compact body, integrated worktable that can be directly embedded into cutting machine

● High precision voltage collection, PWM control DC motor, smooth operation, high sensitivity

Australian FASTCAM Software ( Standard Version ):

Australian FASTCAM (Standard Edition) is the standard software, as automatic nesting and common side cutting, you need to be equipped with SMARTNEST (Expert Edition) or FASTCAM (Expert Edition), which can convert CAD drawings and computer graphics into G codes for cutting parts, then these G code would be stored in USB and put into cutting machine, system can automatically translate the G codes into cutting programs. This machine is equipped with USB interface convenient program transferring. Furthermore, you can set the slit compensation value. Programming software ZZ-TL (optional FASTCAM) is a kind of AutoCAD-based automatic programming and nesting system, and designated software for various CNC cutting machine. The highlighted feature of the machine is that it can help user finishing drawing, programming and nesting to the maximum extent, bring considerable economic benefits for users and easy operation.

① Drawing method: use AutoCAD’s powerful drawing functions for drawing and nesting, automatically generating the necessary cutting codes through DXF, DWG file data processing.

② Cutting technology: the cut-in point can choose to cut from edge or corner; two alternative cut-in way: arc or linear, slit compensation function can calculate the actual cutting track of flame center, cutting path and direction can be set at your will;

③ Nesting means: based on AutoCAD, translation, rotation, replication, mirroring, scaling, array and other operations on part drawings are acceptable and local zoom through window technology.

④ Screen simulation: the actual cutting process can simulate the processing track on the screen, simulate the cutting process, and zoom or move randomly.

⑤ Intelligent nesting software is compatible with R12, R13, R14, A4, 2002, 2004, 2005, 2007 and other version AutoCAD.

Standard Technical Parameters:

Madel

TNC-1325,1530,1830,1840,2030,2040

Frame

Square tube Integral guide

X Y Z Rail

Taiwan HIWIN Linear guide

Transmission

X/Y rack and pinion,Z Taiwan TBI Ball Screw

Motor driver

Stepper Motor driver

Control System

DSP/START

Cutting Thickness

3mm-25mm stainless steel

Plasma Power Supply

63A/100A/160A/200A

Working Speed

8000mm/min

Working Voltage

220-380V,3PH,50/60HZ

Software

ArtCAM/Type 3/Ucancam

Standard ( Optional ) Configuration List:

| Item | Accessories | Model Manufacturer | Configuration Staus | |

| 1 | CNC system | F2300A Shanghai Fangling | Standard | |

| 2 | Electrics | Schneider Electrics - Germany | ||

| 3 |

Motor |

WUZEMING- Changzhou |

||

| 4 |

Drive |

WUZEMING - Changzhou |

||

| 5 |

Speed Reducer |

HUNPHREY - Germany |

||

| 6 |

Gear Rack |

Seven-Stage Gear - Wuxi |

||

| 7 |

Software |

FAST Cam |

||

| 8 |

Z-axis Motor |

T.W.T - Taiwan |

||

| 9 |

Bearing |

SKF- Switzerland |

||

| 10 |

Towing Chain |

High Standard Industrial Nylon Trace Chain |

||

| 11 |

Guide Rail |

HIWIN - Taiwan |

||

| 12 |

Plasma Power |

HUWYUAN - Chengdu |

||

| 13 |

Arc Voltage Height regulator |

HEAVTH HP105 |

||

| 14 |

Software |

SMARTNEST ( Expert Edition) |

Optional |

|

| 15 |

Software |

FASTCAM ( Expert Edition) |

||

| 16 |

Plasma Power |

Hypertherm -USA |

||

| 17 |

Cutting Head |

Hypertherm -USA |

||

| 18 |

Operation System |

STARFIRE-Beijing |

||

|

19 |

Safety Standard |

CE CSA NR-12 OSHA |

||

English

English français

français español

español