Product Item: E21 Hydraulic Torsion Bar Press Brake

The hydraulic press brake is used to bend a variety of metal plates, including stainless steel plates, carbon steel plates, copper plates, aluminum plates, and aluminum alloy plates. With an exceptional strength and low cost, this hydraulic torsion bar press brake is widely used for the production of kitchenware, bathroom accessories, advertisement boards, light-fixtures and hardware, electric equipment and other metal manufacturing applications.

1.Main Features:

1. The whole EU streamlined design, heat treatment rack, high rigidity worktable, optional mechanical crowning device, to achieve precision bending.

2. Hydraulic synchronous control and Estun NC programmable logic controller ensure accurate repeatability and ease use.

3. Integrated hydraulic system (Bosch Rexroth Germany) allows automatically switch to slow bends in a quick way.

4. X axis and Y axis realize accurate positioning function by frequency converter through NC E21 system programming control.

5. Cutting-edge frequency response hydraulic control technology, more stable machine tools, more reliable operation.

6. The best ratio of parameters, optimal core configuration ensure stable performance, more convenient operation.

7. WC67K standard single-axis back gauge system and single-axis bending angle system, you can choose to add the V-axis crowning function, and select the appropriate mold to bend complex shape workpieces easily.

2.Main Configuration:

● Estun E21 NC control system

● Y-axis and X-axis system control adjustment

● Delta frequency converter controls the positioning of X axis and Y axis

● Using HIWIN ball screw and light bar to ensure the accuracy of 0.05mm.

● Front holder support

● Germany Bosch Rexroth hydraulic valve block

● Germany EMB oil tube connector

● Germany Siemens main motor

● France Schneider Electric

● Hydraulic and electrical overload protection

● Top and bottom dies (86 °, R0.6mm, material: 42CrMo)

3.Safety Standard:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

● Front finger protection (safety light curtain)

● South Korea KACON foot switch (Safety grade 4)

● Rear metal safetyguard and CE standard

● Safety relay monitors foot switch, safety protection

● Safety standards (2006/42 / EC):

4. Estun E21 NC Control System:

● Backgauge control

● Control the common motor or inverter

● Intelligent positioning

● Holding pressure unloading time setting

● Workpiece counting

● 40 programs stored, 25 steps per program

● Unilateral positioning

● Concession function

● One-key backup / restore

● mm / inch

●Chinese / English

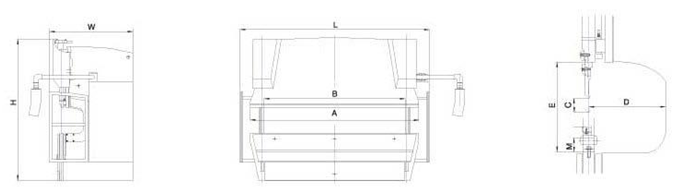

5.E21 Press Brake Technical Parameters:

Model

WC67K

Nominal

pressure

Length of

table(mm)

Distance between

housings (mm)

Main

motor

30T/1600

300

1600

1250

200

80

320

3

1650×950×1650

40T/2200

400

2200

1775

220

120/10

320

4

2300×1500×2000

40T/2500

400

2500

1975

220

120/10

320

4

2600×1500×2000

63T/2500

630

2500

2035

260

120/10

370

5.5

2600×1600×2300

63T/3200

630

3200

2535

260

120/10

370

5.5

3300×1600×2300

80T/3200

800

3200

2540

320

120/10

380

7.5

3300×1700×2300

80T/4000

800

4000

3240

320

120/10

380

7.5

4100×1700×2300

100T/3200

1000

3200

2560

320

120/10

380

7.5

3300×1800×2400

100T/4000

1000

4000

3160

320

120/10

380

7.5

4100×1800×2400

125T/3200

1250

3200

2600

320

120/10

380

7.5

3200×1750×2520

125T/4000

1250

4000

3100

320

120/10

380

7.5

4000×1750×2520

160T/3200

1600

3200

2550

350

180/6

470

11

3300×1600×2600

160T/4000

1600

4000

3250

350

180/6

470

11

4100×2000×2600

160T/6000

1600

6000

4740

350

180/6

470

11

6100×2000×2600

200T/3200

2000

2000

2540

350

250/5

480

15

3300×2100×2800

200T/4000

2000

2000

3140

350

250/5

480

15

4100×2100×2900

200T/5000

2000

2000

3940

350

250/5

480

15

5100×2100×3000

250T/4000

2500

2500

3120

400

250/4

540

18.5

4100×2200×3500

250T/5000

2500

2500

3920

400

250/4

540

18.5

5100×2200×3500

250T/6000

3000

3000

4720

400

250/4

540

18.5

6100×2200×3500

300T/5000

3000

3000

3910

400

250/3

560

22

5100×2600×4000

300T/6000

3000

3000

4710

400

250/3

560

22

6100×2600×4000

300T/7000

3000

3000

5620

400

250/3

560

22

7100×2600×4400

320T/7000

3200

3200

5620

400

250/2.5

560

22

7100×2600×4400

350T/6000

3500

3500

5100

400

250/2.5

560

30

6100×2600×4200

350T/7000

3500

3500

5620

400

250/2.5

560

30

7100×2600×4500

400T/4000

4000

4000

3100

400

300/2.5

600

30

4100×2700×3800

400T/6000

4000

4000

4880

400

350/2.5

620

30

6100×2800×4200

500T/5000

5000

5000

4100

400

350/2.5

630

37

5100×3000×4400

500T/6000

5000

5000

4820

400

350/2.5

630

37

6100×3000×4700

500T/7000

5000

5000

5620

400

350/2.5

630

37

7100×3000×4900

600T/6000

6000

6000

4820

400

350/2.5

630

45

6100×2965×4700

600T/7000

6000

7000

5620

400

350/2.5

630

45

7100×2965×4900

6. Standard/Optional Configuration List:

| No | Accessory Name |

Model / Manufacturer |

Configuration |

| 1 |

CNC System |

■E21 NC System Estun |

Standard |

| 2 |

Electrics |

Germany Schneider Electric / Travel switch & Limit switch |

|

| 3 |

Main Motor |

Siemens Motor |

|

| 4 |

Back gauge, synchronous belt, synchronous wheel |

Taiwan, China positioning control / Guaranteed precision |

|

| 5 |

Frequency Converter |

JRACDRIVE positioning control / Guaranteed precision |

|

| 6 |

Pedal Switch |

South Korea KACON |

|

| 7 |

Backgauge |

Ball screw linear guide rail-Taiwan HIWIN |

|

| 8 |

Hydraulic system |

Bosch Rexroth-Germany |

|

| 9 |

Oil Pump |

SUNNY-USA |

|

| 10 |

Sealing Ring |

PARKER-America |

|

| 11 |

Oil Tube Connector |

Casing connector |

|

| 12 |

Front Safety Guard |

Produced by DURMA CNC |

|

| 13 |

Back Safety Guard |

Produced by DURMA CNC |

|

| 14 |

Die |

One set of standard dies |

|

| 15 |

Clamping |

General clamping tools |

|

| 16 |

Crowning Mode |

Hydraulic crowning |

Optional |

| 17 |

Crowning Mode |

Mechanical crowning |

|

| 18 |

Laser Protection |

DSP- Italy |

|

| 19 |

Front Photoelectric Protection |

LNTECH-Shandong |

|

| 20 |

Back Photoelectric Protection |

LNTECH-Shandong |

|

| 21 |

Clamping |

Quick clampings |

|

| 22 |

System Options |

E200P、DA41S |

|

| 23 |

Safety Standard |

■CE □CSA ■NR-12 □OSHA |

7.Fabrication Equipment:

|

Overall Welding Fabrication overall welding fabrication of workbench vertical plate and machine body ensures the plates of the workbench

Precise Boring Bore Overall fabricating of fixed seat and fixed hole ensures the two oil cylinder in the same level,namely,with same Y axis value when working.to protect the oil cylinder and machine

Finite Analysis Workbench adopts finite-element analysis curve fabricating, avoiding uneven pressure,and reducing the cutting linearity deviotion

CNC Machine Center All the machine components are manufactured in CNC machining center, ensuring the accuracy of each component.

Heat Treatment by Tempering Furnace Machine frame and slider hardened by heat treatment to guarantee the frame strength the service life,and improve the bending accuracy. |

English

English français

français español

español