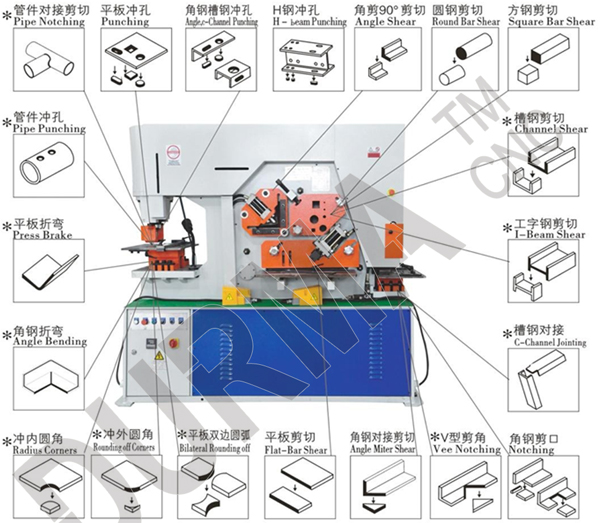

Product Item: Ironworker Machine Q35Y Series

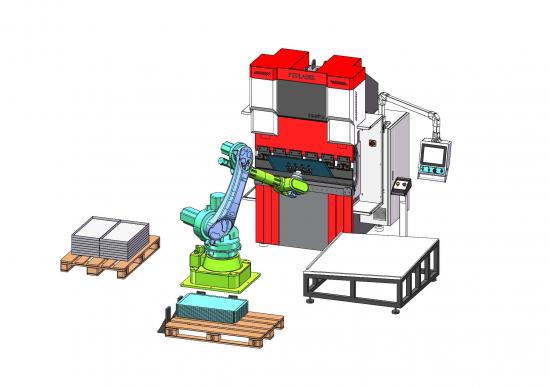

Structure and performance introduction:

1)This series of hydraulic ironworker machine is ideal equipment for cutting all kinds of angle steel, I-beam, U-shape steel, right angle or 45 degree angle steel. Multi-workstations make it possible to finish series operations simultaneously on one machine, such as punching, shearing and notching, Dual-piston-type combined punching and shearing machine allows two-man operation at the same time (stamping +another work station), German Rexroth’s integrated hydraulic valve block ensures the stability of the machine, Through Thermal Effect of annealing processing, the entire rack is able to keep its shape forever, without deformation. The introduction of imported brand accessories ensures the parts ’ service life and use precision.

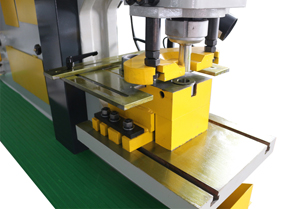

2)Punching: effective punching can be achieved with the machine, and stamping die is easy to be replaced.

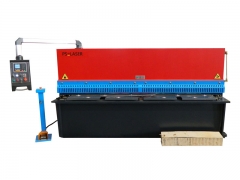

3)Bar cutting: you can quickly cut the round bar and square steel, if you want to cut U-shaped, I-beam or T-profile section steel only by exchanging the cutting blade and the operation procedure is very simple.

4)Angle cutting: you can cut several 90 ° and 45 ° angles with the help of special dies.

5)Metal Sheet Bending: it is very easy to fulfill the daily metal sheet bending work by making the bending moulds.

6)Notching: The machine is equipped with a large-shaped slotting blade head, which can meet your general use, as to, special shaping blade head can be customized.

Hydraulic Ironworker Machine Main functions:

1)2 independent hydraulic piston rods and foot-pedal allows two people operating at the same time.

2)More efficient stroke-control functions of piston rod.

3)Central lubricating system

4)Motor-driven rear stopper

5)Lighting devices for work

6)5 independent work-positions: punch pin and die (standard punching dies),cutting blade group for round and square steel, shearing blades for steel plate, slotting and angle-cutting blade.

Punching And Shearing Machine Technical Specifications:

|

Technical Specifications |

Q35Y-30 |

|||

|

Punching Pressure(T) |

160 |

|||

|

Depth of throat(mm) |

600 |

|||

|

Features |

Punching holes |

Diameter Max thickness |

mm |

38x26 |

|

Diameter thickness |

mm |

38x26 |

||

|

Max diameter |

mm |

36 | ||

|

Stroke |

mm |

80 | ||

|

Work stroke |

mm |

x30 | ||

|

Throat Depth |

mm |

600 | ||

|

Steel bar cutting |

Round steel |

mm |

65 | |

|

Square steel |

mm |

55x55 | ||

|

Angle cutting |

Angle cutting |

mm |

180x180x16 | |

|

Angle |

°(degree) |

80x80x10 | ||

|

Edged surface |

mm |

11.5 | ||

|

Slotting |

Thickness |

mm |

280 | |

|

Width |

mm |

86 | ||

|

Depth |

mm |

|

||

|

U-shaped and I-beam cutting |

mm |

180x180x16 | ||

|

T-section cutting |

mm |

80x80x10 | ||

|

I-beam cutting |

mm |

280x124x10.5 | ||

|

V-slotting die |

mm |

600 | ||

|

V-bending |

mm |

26 | ||

|

Pressure |

kn | 1600 | ||

|

Motor Power |

kw | 15 | ||

|

Weight |

kg | 6800 | ||

|

Machine outline size( L x W x H ) |

mm | 3680x1040x2300 | ||

| Please contact us for other parameters. | ||||

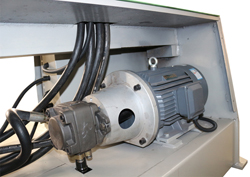

Standard Configuration List ( Optional ):

No

Item

Manufacturer

Remarks

1

Electrics

Schneider - France

Standard

2

Main motor

Siemens - Germany

3

Oil pump

SUNNY - USA

4

Valve block

Rexroth - Germany

5

Pedal switch

KACON - South Korea

6

Wind-cooler for oil

China

7

Sealing ring

Parker - USA

8

Oil pipe connector

pressure hose - Germany

9

Safety guard

DURMACNC

10

Manual stopper positioning

DURMACNC

Optional

11

Electric stopper positioning

DURMACNC

12

Automatic holding system ( Manual & Automatic)

DURMACNC

13

Infrared ray positioning ( Punching position )

China

14

Tandem (punching part and shearing)

DURMACNC

English

English français

français español

español