Dimensions and Design Considerations for Panel Bending

With each panel bending project, there are certain design considerations and dimensions that influence the workpiece’s outcome.

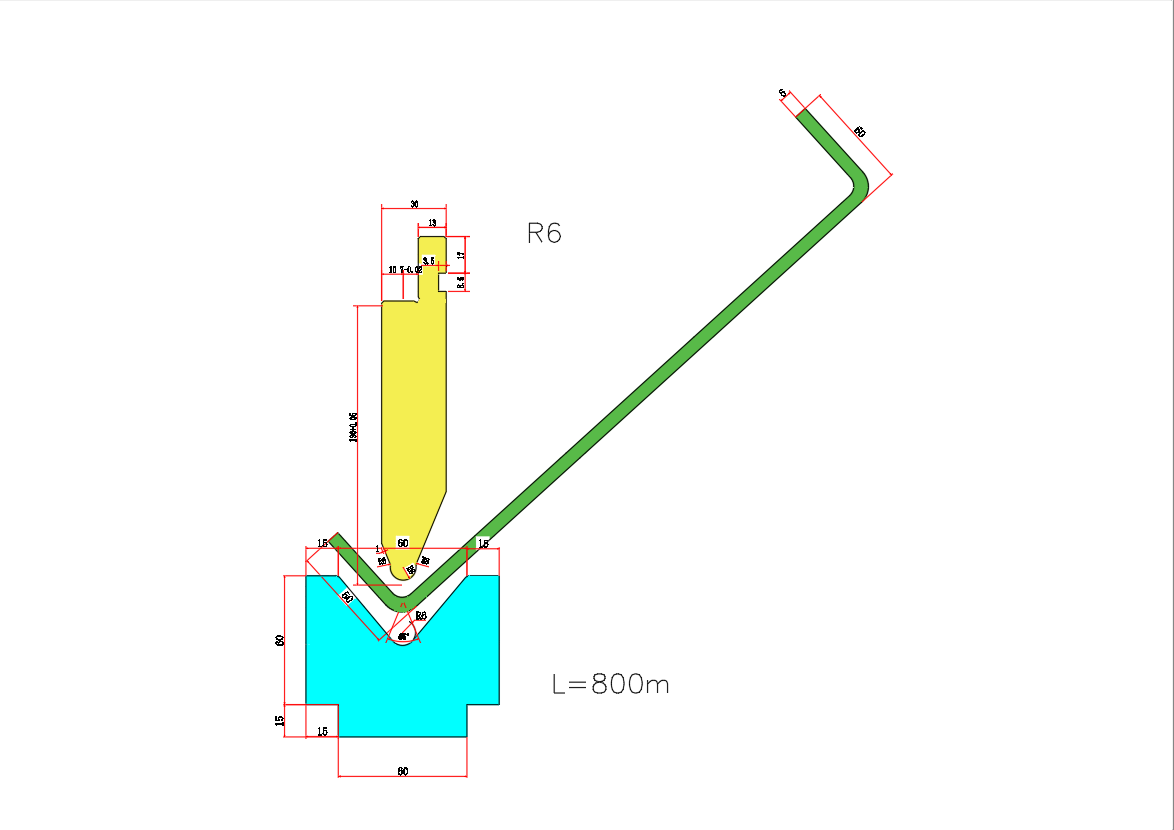

Bend Line

The bend line is a straight line on either side of a panel bend that shows the start and end of a bend.

Bend Radius

The bend radius is the distance between the axis of the bend and the bend’s interior surface. The most frequently used radius is a 90° angle. To save time and money, Metal Works can bend up or down on the same plane for more efficient production.

Parts often need to be overbent to achieve the ideal radius and bend angle due to residual stress in the material following bending, which is known as springback. The minimum bend value depends on the specific material and application, but the bend radius in most applications should be at least equal to the material thickness, which helps prevent fracturing.

Bend Angle

The bend angle, or inside bend radius, is the angle from the bent flange to its starting position before bending. The inside bend radius plus the sheet thickness will give you the outside bend radius.

Neutral Axis

The neutral axis is the part of the metal sheet that remains uncompressed and unstretched. It stays at a constant length.

K-factor

This defines where the neutral axis is within the bending material. The formula for calculating the K-factor involves dividing the neutral axis (T) by the sheet thickness (t). The value of the K-factor tends to be higher than 0.25 but below 0.5.

Bend Allowance

The bend allowance is the bend’s arc length or the neutral axis length between the bend lines. You can use bend allowance to calculate the total flat length, specifically by adding the bend allowance to the flange lengths.

Bend Relief

Applications use bend reliefs if a bend extends on an edge. The bend relief must not be deeper than the combination of the bend radius and material thickness. To prevent tearing, the bending process requires a relief notch.

Bend Height

The bend height (H) needs to be a minimum of four times the thickness (t) of the sheet added to the bend radius (r). Otherwise, a bend height that’s too small will lead to part deformation. The formula for calculating bend height is as follows: H = 4t + r.

Bending Near Holes

Panel bending near holes on a workpiece can result in hole deformation.

English

English français

français español

español