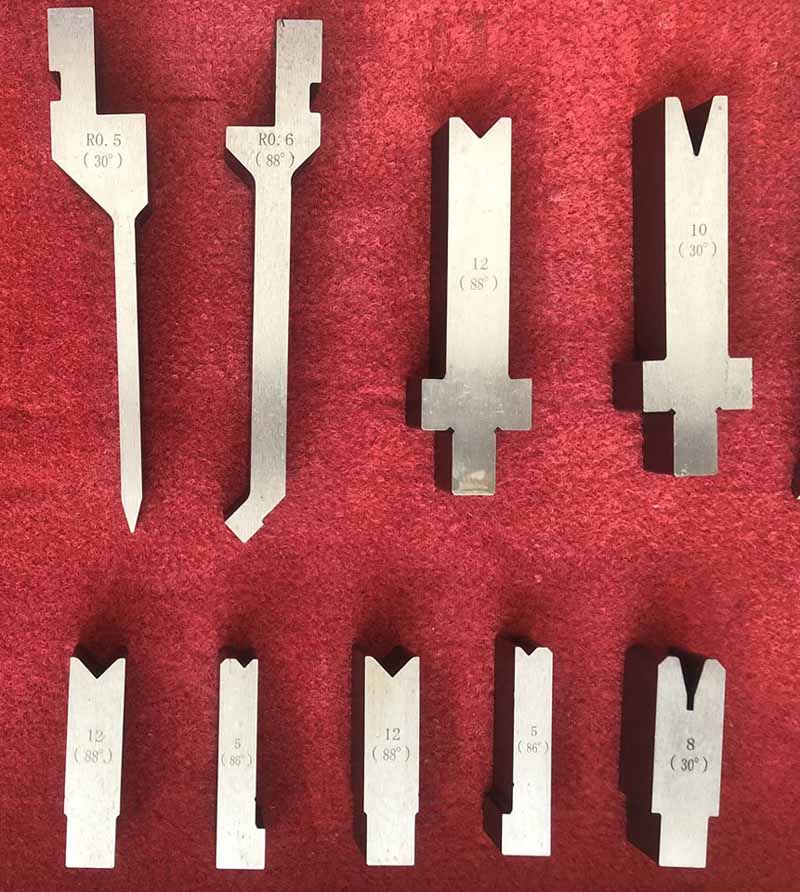

Upper mold part: straight sword, straight sword (large, small) machete, gooseneck (large, medium, small) machete, 30-degree sharp knife, flattening knife, simple mold, special mold, arc cutter, etc.

Lower mold part: double V slot V4-V7 V5-V9 V6-V10 V7-V11 V8-V12 V15-V18 and so on.

Single V slot V4 V5 V6 V7 V8 V10 V12 and so on.

Mold base part: single groove mold base and double groove mold base. There are three types of double slots: low station (55cm), middle station (75cm) and high station (135cm).

Second, different materials because of their different structures, the tools used are not the same, the resulting acid and alkali resistance, tensile strength, material hardness, tensile coefficient, plasticity, etc. are all different. When selecting a mold, you can make a reasonable choice according to the pressure, structure, material, unfolded size of the workpiece, process requirements, and surface treatment. In general, the width of the slot of the lower die for the iron plate can be 5-6 times the thickness of the material, not less than 4 times, and not more than 8 times. The notch of the stainless steel selection lower die is 6-8 times the thickness of the material and not less than 5 times. The notch of the die for aluminum and copper can be 8-10 times the thickness of the material (the surface crack should be avoided when bending).

Third, the choice of the upper mold according to the workpiece avoidance, nail, nut and other structures to make a reasonable choice, when the workpiece needs left and right avoidance can choose the machete or left and right ear knife, you can also use special molds.

The lower die is installed according to the shape of the workpiece, and the lower die is mainly installed or reversed. It is mainly used for avoiding position and nail. When the size of the workpiece is smaller than the normal size and the unrolled size is too small, the lower mold eccentricity method can be used to complete the safety production. The reasonable eccentricity is 1/4 of the V groove width.

When the ratio of the V-groove to the thickness of the material is 6 times, the expanded size of the work piece should be increased or decreased by 0.10 mm for each increase or decrease of one unit (1 mm). When it reaches the limit, there is no obvious change.

The selection of the special mold is based on the structure's own shape, performance, size, appearance, the safe height of the machine, and the pressure of the machine. The adjustment of the segment differential mold is to adjust the size of the workpiece in the middle of the mold according to the size requirement of the workpiece to control the size of the workpiece.

English

English français

français español

español