-

Groover, also been called V groover, V grooving machine. It is a machine for scribing and slot V-shaped grooves at the positions where metal plates need to be bent. This can reduce the bending radius and make the sheet metal workpiece more beautiful. It is applicable to industries requiring high-precision plate processing, such as elevators, packaging materials, stainless steel processing, househo...

read more

-

8 ways to keep your shear in top shape Shears are common pieces of fabricating equipment that can be found in many metal forming plants. From tube mills to small fabricators, the shear is one of the most critical and diverse tools used in metal fabricating. Varying in size from small hand-held metal shears and foot-operated trim shears to high-production in-line flying cutoffs, the modern metal sh...

read more

-

How To Maintain Shearing Machines Correctly The metalworking industry has come a long way from saws and blades. Yet, as high-tech as modern metalworking devices are, they still need to be adequately taken care of. This resourceful guide will show staff members and their employers how to maintain shearing machines correctly so that replacements aren’t needed for a while. Fabricators ought to pay cl...

read more

-

Why Deburring Is Important for Metal Fabrication Projects Metal fabrication is more than just cutting a part; it’s an all-encompassing process of conceptualization, design, iteration, prepping, cutting and post-processing. All team members must take meticulous steps to ensure that every step is completed correctly. An important step that is commonly overlooked is post-processing. This article will...

read more

-

The Most Common Types of Steel for Metal Fabrication Steel has become ubiquitous in American life. Most people recognize structural steel when they see skyscrapers under construction. We can find stainless steel in our dining utensils and appliances. And carbon steel is often used to create lightweight yet strong bicycle frames. Steel is made of iron and carbon. Different types of steel have diffe...

read more

-

Tips to Stay Safe When Operating a Hydraulic Press Hydraulic presses are incredibly versatile machines. The tools can manipulate various materials into different shapes. Therefore, people can find hydraulic presses in machine shops around the world. As essential as these devices are, they can also put operators in harm’s way if they don’t take the proper precautions. This article will de...

read more

-

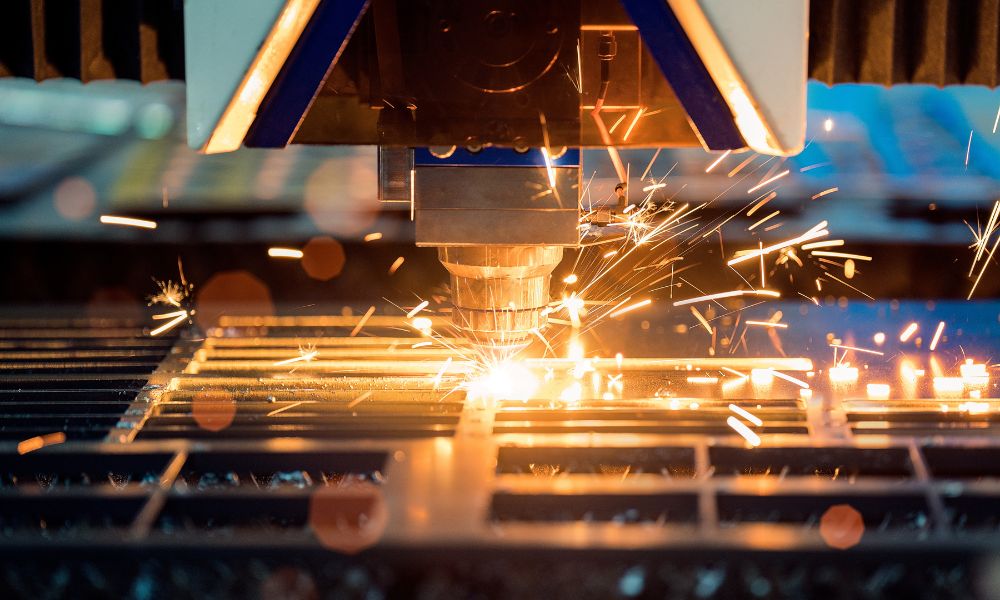

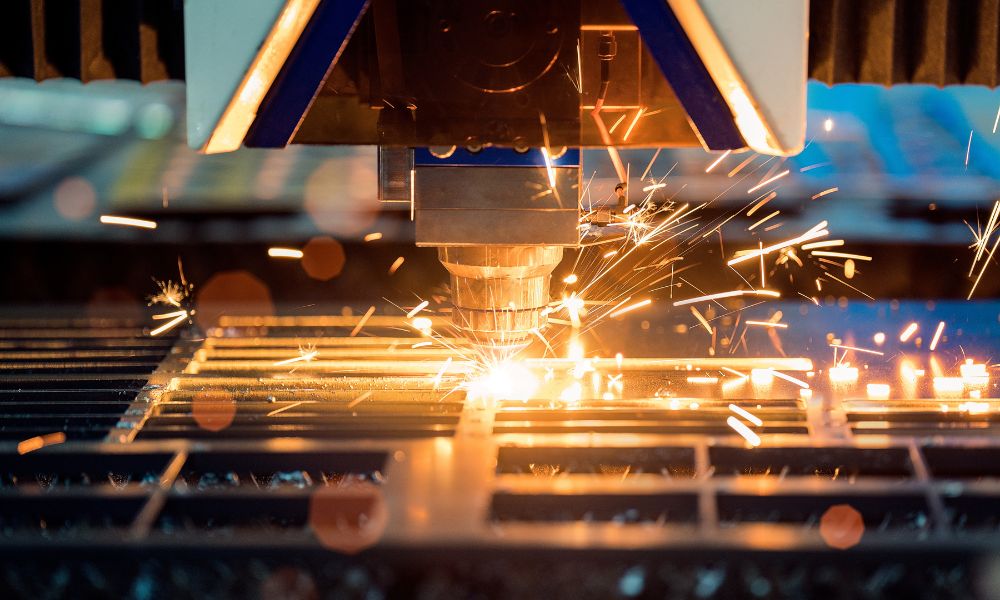

4 Ways You Can Reduce Laser Cutting Costs Laser cutting machines offer precision and speed for metal fabrication shops that cut or engrave thin metals, wood, plastic, or leather. The machines represent a major investment, plus ongoing costs of maintenance, training, and personal protective equipment for team members. These four ways you can reduce laser cutting costs should keep your operation run...

read more

-

Ways To Market Your Metal Fabrication Business Many businesses thrive on referrals and a reputation for excellent service. But if clients don’t know you’d appreciate a referral, and no one knows about your shop’s stellar reputation, these things won’t translate into growth. Learn ways to market your metal fabrication business here. Optimize Your Online Presence Prospective purchasers of goods and ...

read more

-

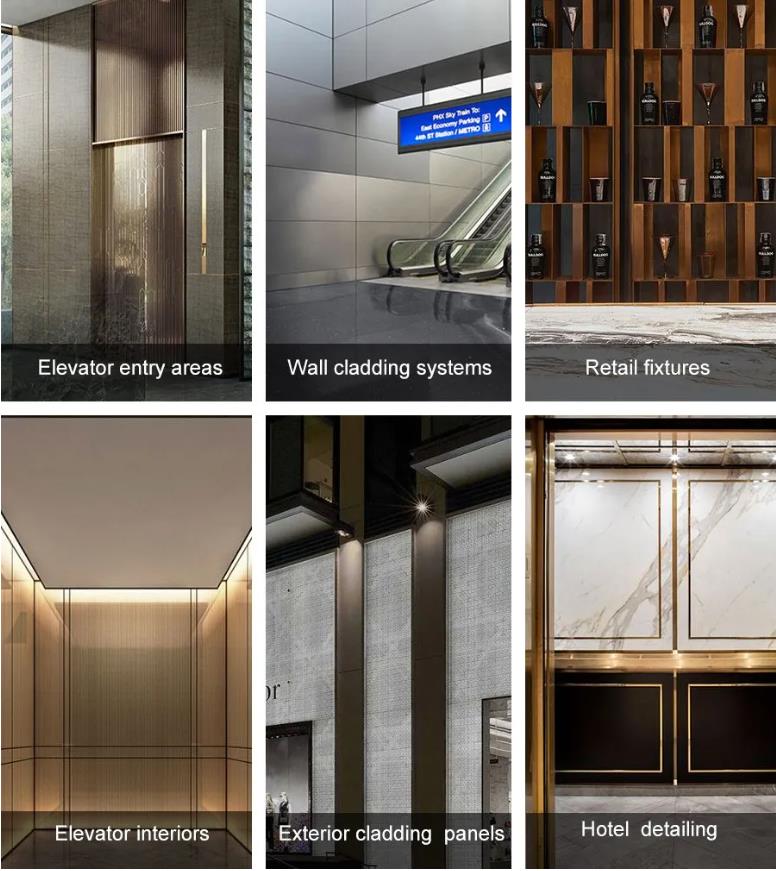

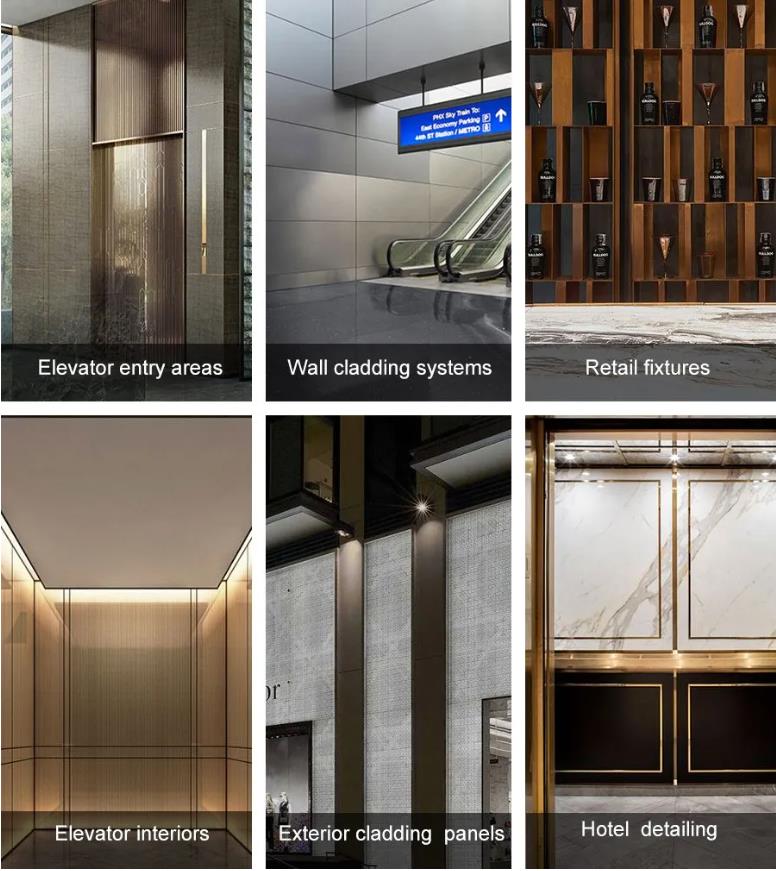

Metal fabrication shops manipulate sheet metal in many different ways to create the sizes, shapes, and appearances their customers desire. Anytime these operations cut metal to specific measurements, they are preparing a customized product. They commonly use these five custom sheet metal fabrication techniques to produce the required metal forms. Rolling In its most fundamental form, the metals th...

read more