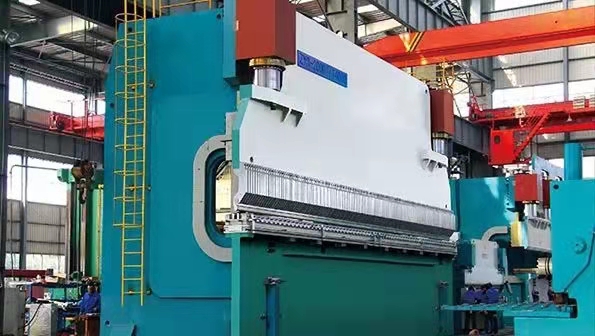

Press Brake (Metalworking)

A press brake is a machine tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the work-piece between a matching punch and die. Typically, two C-frames form the sides of the press brake, connected to a table at the bottom and on a movable beam at the top. The bottom tool is mounted on the table with the top tool mounted on the upper beam.

Press brakes can be used for many different forming jobs with the right die design. Types of dies include:

- V-dies—the most common type of die. The bottom dies can be made with different-sized die openings to handle a variety of materials and bend angles.

- Rotary bending dies—a cylindrical shape with an 88-degree V-notch cut along its axis is seated in the “saddle” of the punch. The die is an anvil over which the rocker bends the sheet.

- 90 degree dies—largely used for bottoming operations. The die opening dimension depends on material thickness.

- Acute angle (air-bending) dies—used in air bending, these can actually be used to produce acute, 90 degree, and obtuse angles by varying how deeply the punch enters the die by adjusting the ram.

- Gooseneck (return-flanging) dies—The punch is designed to allow for clearance of already formed flanges

- Offset dies—a combination punch and die set that bends two angles in one stroke to produce a Z shape.

- Hemming dies—two-stage dies combining an acute angle die with a flattening tool.

- Seaming dies—There are a number of ways to build dies to produce seams in sheets and tubes.

- Radius dies—A radius bend can be produced by a rounded punch. The bottom die may be a V-die or may include a spring pad or rubber pad to form the bottom of the die.

- Beading dies—A bead or a “stopped rib” may be a feature that stiffens the resulting part. The punch has a rounded head with flat shoulders on each side of the bead. The bottom die is the inverse of the punch.

- Curling dies—The die forms a curled or coiled edge on the sheet.

- Tube- and pipe-forming dies—a first operation bends the edges of the sheet to make the piece roll up. Then a die similar to a curling die causes the tube to be formed. Larger tubes are formed over a mandrel.

- Four-way die blocks—A single die block may have a V machined into each of four sides for ease of changeover of small jobs.

- Channel-forming dies—A punch can be pressed into a die to form two angles at the bottom of the sheet, forming an angular channel.

- U-bend dies—Similar to channel forming, but with a rounded bottom. Spring back may be a problem and a means may need to be provided for countering it.

- Box-forming dies—While a box may be formed by simple angle bends on each side, the different side lengths of a rectangular box must be accommodated by building the punch in sections. The punch also needs to be high enough to accommodate the height of the resulting box’s sides.

- Corrugating dies—Such dies have a wavy surface and may involve spring-loaded punch elements.

- Multiple-bend dies—A die set may be built in the shape of the desired profile and form several bends on a single stroke of the press.

- Rocker-type dies—A rocker insert in the punch may allow for some side-to-side motion, in addition to the up-and-down motion of the press.

English

English français

français español

español